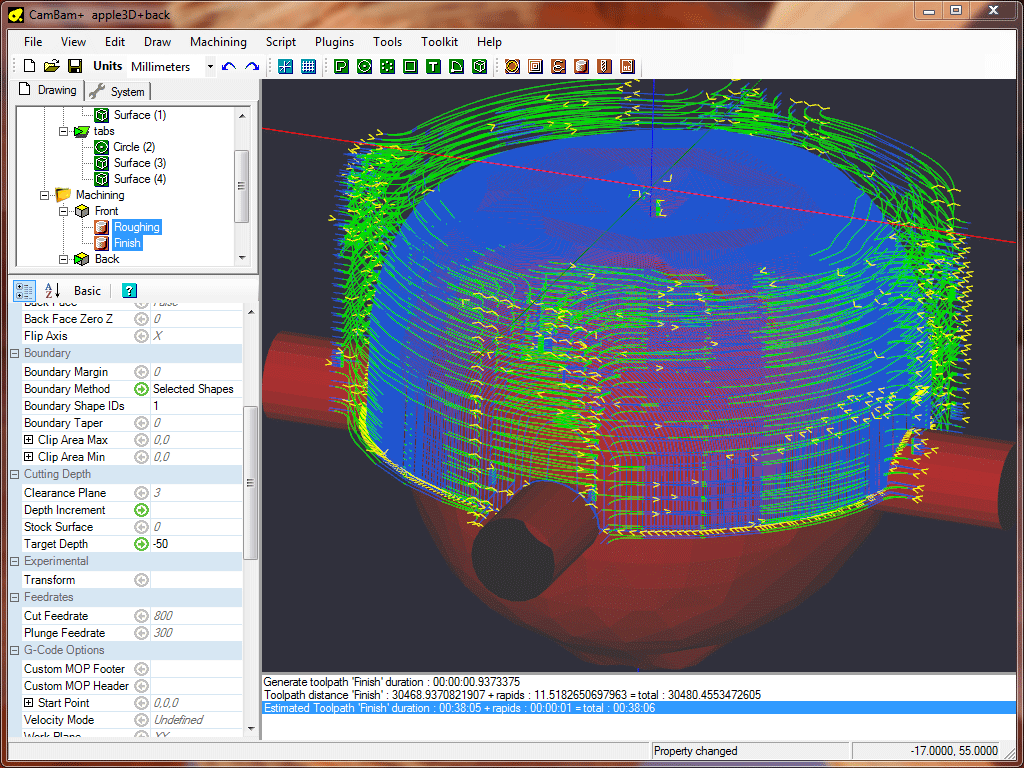

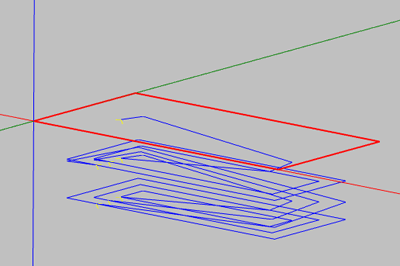

This is the Z offset of the stock surface at which to start machining. The feed rate to use for crossover moves. The cut is increased by this amount each step, expressed as a fraction (0-1) of the cutter diameter. The start point circle can be moved by clicking and dragging If a start point is defined, a small circle will be displayed at this point when the machining operation is selected. The speed in RPM of the spindle Used to select a point, near to where the first toolpath should begin machining. See the side profiles reference for more information. A composite properties that enables the creation of pseudo 3D objects from 2D shapes by creating radii and slopes. The direction of rotation of the spindle. Negative values can be used to oversize cuts. Remaining stock is typically removed later in a finishing pass. This is the amount of stock to leave after the final cut. List of drawing objects from which this machine operation is defined. PlungeFeedrate PrimitiveIds RoughingClearance The feed rate to use when plunging. None - Toolpaths are not optimised and are written in the order they were generated. Experimental - A new, hopefully improved optimiser that is currently in testing. Default - Toolpaths are ordered to minimise rapids. OptimisationMode An option that controls how the toolpaths are ordered in gcode output. This is output in the gcode as a comment and is useful for keeping track of the function of each machining operation. Name Each machine operation can be given a meaningful name or description. If the distance to the next toolpath exceeds MaxCrossoverDistance, a retract, rapid and plunge to the next position, via the clearance plane, is inserted.Ĭontrols the direction the cutter moves around the toolpath.Ĭonventional or Climb milling supported. See LeadInMove for a description of the LeadOutMove sub properties Maximum distance as a fraction (0-1) of the tool diameter to cut in horizontal transitions. TangentRadius : The radius of the tangent lead inĭefines the type of lead out move to use. LeadInType : None | Spiral | Tangent SpiralAngle : Used by spiral and tangents to control ramp angle. For open shapes there is not inside or outside, so the point order controls which side of the line to cut. See the holding tab reference for more information.Ĭontrols whether to cut Inside or Outside the selected shapes. Defines holding tabs (bridges) to prevent cut parts moving while cutting. The depth increment of the final machining pass. If Enabled is true, the toolpaths associated with this machining operation are displayed and included in the gcode output. If this width is greater than the tool diameter, multiple parallel cuts are used. Controls whether to cut to depth first or all cuts on this level first. A multi-line gcode script that will be inserted into the gcode post before the current machining operation. This will result in some stock overcutting but is useful in cases where machined parts will be fitted together such as slot joints or inlays.ĬustomMOPFooter CustomMOPHeader CutFeedrate CutOrdering CutWidth DepthIncrement Enabled FinalDepthIncrement HoldingTabsĪ multi-line gcode script that will be inserted into the gcode post after the current machining operation. Set CornerOvercut to True to add an extra machining move, which will cut into inside corners that would not ordinarily be cut. Makes sure adjacent toolpaths do not overlap.

#Add stock to cambam free#

The clearance plane should be clear of the stock and any holding devices to allow free movement to any location. PropertiesClearancePlane The clearance plane (offset from the work plane). Lead in moves and holding tabs are supported.

Cuts can be inside or outside a selected shape. Other uses include facing edges and with increased cut widths can be used to create pockets.

Profile Machining OperationA 2.5D Profile machining operation is typically used to cut out shapes.

0 kommentar(er)

0 kommentar(er)